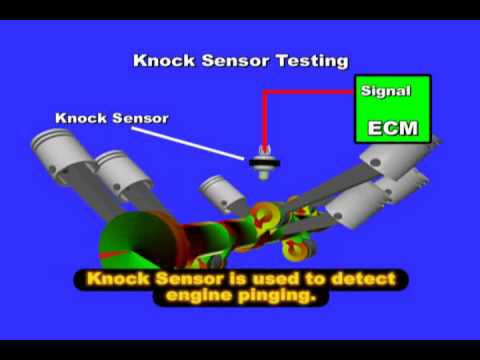

Α knocking vibration from the cylinder block is sensed as vibrational pressure by the Knock Sensor . This pressure is converted into a voltage signal and sent to the ECM. The ECM uses the Knock Sensor signal to control the timing.

Engine knock occurs within a specific frequency range. The Knock Sensor, located in the engine block, cylinder head, or intake manifold is tuned to detect that frequency.

Inside the knock sensor is a piezoelectric element. Piezoelectric elements generate a voltage when pressure or vibration is applied to them. The piezoelectric element in the Knock Sensor is tuned to the engine knock frequency.

The vibration from the engine knocking vibrates the piezoelectric element generating a voltage. The voltage output from the Knock Sensor is highest at this time.

Engine knock occurs within a specific frequency range. The Knock Sensor, located in the engine block, cylinder head, or intake manifold is tuned to detect that frequency.

Inside the knock sensor is a piezoelectric element. Piezoelectric elements generate a voltage when pressure or vibration is applied to them. The piezoelectric element in the Knock Sensor is tuned to the engine knock frequency.

The vibration from the engine knocking vibrates the piezoelectric element generating a voltage. The voltage output from the Knock Sensor is highest at this time.

No comments:

Post a Comment